To secure its imports and exports of Liquefied Natural Gas (LNG), the KUWAIT / NATIONAL PETROLEUM COMPANY (KNPC) has launched the construction of a giant terminal on the Al-Zour site.

The project, which must be completed in 2020, consists of building a regasification plant (USD 1.39bn) and 8 storage tanks with an individual capacity of 225,000 m3 (USD 1.52bn), all located

on a platform reclaimed entirely from the sea.

This major “Design & Build” contract was won by HYUNDAI ENGINEERING & CONSTRUCTION, which entrusted the design to the Korean firm KOGAS TECH, specialized in engineering and maintenance of onshore and offshore gas facilities.

After consulting several international geotechnical engineering companies, KOGAS TECH entrusted TERRASOL with the design of the tanks foundations. These eight pre-stressed concrete structures, with a diameter of 90 m and height of 45 m, must in particular be able to withstand strong seismic accelerations with a return period of 2475 years.

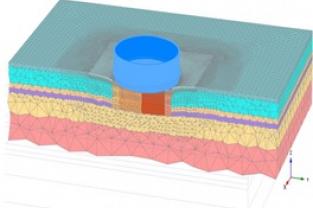

HYUNDAI ENGINEERING & CONSTRUCTION has selected a Disconnected Pile Raft foundation system. TERRASOL’s wealth of expertise and experience in this field (analytical design approach, technical management of the ASIRI project, and previous collaborations with HYUNDAI) proved decisive for this project.

TERRASOL provided static justification for the inclusions and distribution layer, and also determined the seismic response of the site using SHAKE program, which enabled the dynamic impedances of the foundation system to be defined (using SASSI program) with the right degradation functions for the shear moduli. On this occasion, we called for Alain Pecker’s expertise to calibrate seismic design spectra.

Terrasol’s achievements:

- Static justification for the inclusions and distribution layer

- Determination of the seismic response of the site using SHAKE program

- Evaluation of the dynamic impedances of the foundation system using SASSI program

Agent Access

Agent Access